Web-based job tracking software

- Track job status across your company in real time

- Cut down on job status meetings

- Step up from using paper or spreadsheets

- Import job data from spreadsheets, MRP, ERP, accounting, etc

- Web based software, can be used with tablets

- Extensive user permission controls

Benefits

In MaxScheduler most scheduling actions are done using your mouse. Also there are no enforced business rules to fight against.

Scheduling system that is always up to date. This means everyone in your organization can log in and check the schedule themselves. Reduces the need for phone calls, emails, chasing people down, etc. Great for sales people who are on the road, customer service, management, etc.

MaxScheduler can work with other software system(s) that you are using to run your business. Types of systems would be ERP, MRP, MIS, Job Shop, Accounting, spreadsheets etc.

MaxSchedulerWeb can be used by the following manufacturing businesses: print shops, jobs shops, make to order, make to inventory,

plastic injection, wire harnesses, CNC shops, metal plating factories, tool and die, aggregate, cement, machine repair, t-shirt printing, etc.

Features

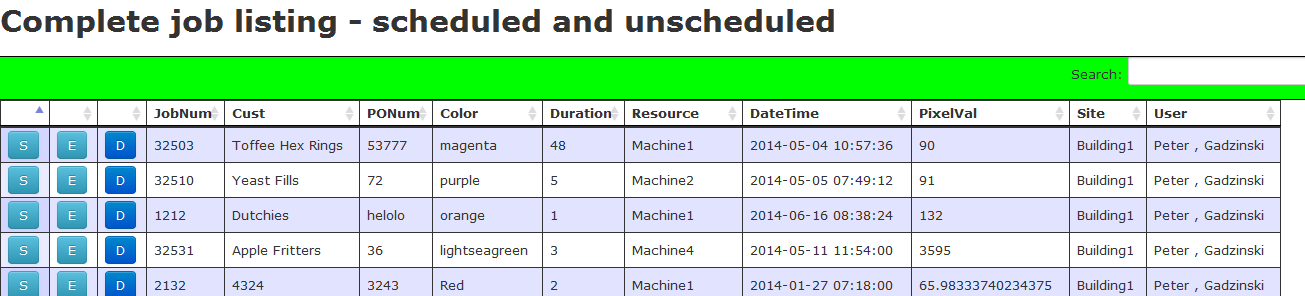

Reporting - Job Status

There is a overall Job status screen that lets you see all job details. For example check if the job is currently scheduled or not. There are easy to use, excel like features like column sortation and filtering. There is also an Excel export option. This lets you do your only analysis or importing into another system.

There is a overall Job status screen that lets you see all job details. For example check if the job is currently scheduled or not. There are easy to use, excel like features like column sortation and filtering. There is also an Excel export option. This lets you do your only analysis or importing into another system.

Scheduling software is accessible through any web browser on computer, laptop, tablet or smart phone.

Control schedule access through User profiles

There are many User level controls. This allows for a wide range of access. On one side, Schedulers often have full access to the system. The other extreme, there are Viewers, which can see the schedule, but not make changes.

There are many User level controls. This allows for a wide range of access. On one side, Schedulers often have full access to the system. The other extreme, there are Viewers, which can see the schedule, but not make changes.

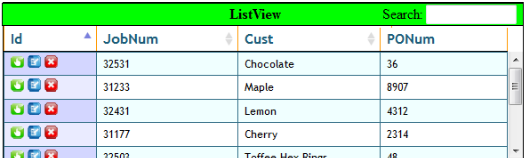

Data import

Job data can be imported into MaxScheduler to reduce clerical error. Useful if you have data in systems such as MRP, ERP, WMS, Job Shop, spreadsheets, accounting, etc. MaxScheduler does work with Zapier.

Job data can be imported into MaxScheduler to reduce clerical error. Useful if you have data in systems such as MRP, ERP, WMS, Job Shop, spreadsheets, accounting, etc. MaxScheduler does work with Zapier.

Sample of MaxScheduler Customers

Printing

Manufacturing

Delivery Planning

Manufacturing

Printing

Printing

Warehousing

Manufacturing

Manufacturing

Manufacturing

Printing

Manufacturing

Customer Testimonials

"Our old ERP software Process Pro did not have a very good scheduler so we started to research to see what we could find that would just allow us to build the type of scheduler we wanted and needed. We found Max Schedular and it was like night and day. Completely turned our production around, decreased our lead times, improved our productivity and in turn we have increased sales.""

Jeff G., Supplements Industry

“We’ve been using Maxscheduler for several years now. It is the quickest, simplest way for us to schedule our small manufacturing plant. It’s been a game changer for us. We’ve found nothing like Maxscheduler. It is the perfect tool for scheduling our production floor. It’s robust and flexible. The support from the company has been excellent too!”

Chris J. - Consumer Display Industry

"MaxScheduler has been a lifesaver for us. It is quick and easy and allows me to schedule our production visually. Peter is always available to help if we have any questions. We have never had any downtime with MaxScheduler either. It just plain works!"

Bryan K. - Rubber Industry

"Max Scheduler was the right size, elegant solution, to help solve our immediate problem"

Al S. - Warehouse manager

Read more what Al Saltemachea was looking for in a receiving door scheduler

"We have a complete MRP system with a scheduler already, but it is so complicated and rigid that we never used it. Our production people already know the last minute constraints for each work center, so we really just needed “a white board” that Sales, Production, and Purchasing could see and have input to in real time. Also, I travel quite a bit so I need to see the latest up to date schedule as well. So putting it all together, MaxScheduler was the answer! We use it daily and it’s been great."

William S. - President - Controls Industry

"We were looking for a solution to some workflow issues we were having within our print studio. After looking online, Max Scheduler stood out as the simplest yet most suitable tool for organising our workflow. It created transparency within the company, especially as our staff are based in different locations yet all need to see what's going on within the print studio. We've also received excellent support when setting up the scheduler and can highly recommend this tool for anyone looking to work from a single online schedule."

Katie M. - Accounts - Media Agency

"There is no way possible we could possibly keep straight the number of Work Orders, Bins of Parts, and Quantity of Parts without MaxScheduler. There is no way possible we could respond to multiple customer requests daily.Quantifying benefits isn’t easy – but every member of the Production Team will state that we could not operate today with MaxScheduler."

Rick Chalmers - Quality Manager - EZ Industrial Solutions

Ways to use MaxScheduler

Supplement manufacturingScheduling with AI - Artificial Intelligence

Machine scheduling

Manufacturing scheduling

Print Shop scheduling

Wallboard scheduling

Spreadsheet scheduling

Delivery Planning

Job tracking software

Manufacturing Jobs with Routes

Capacity Planning software

Google Sheets scheduler

QuickBooks scheduler

Industrial scheduler with Zapier Integration

Configuration

Benefits

Contact Us

sales@MaxScheduler.comsupport@MaxScheduler.com

416 702 7387